-

FBE/PE Coated Welded Steel Pipe

FBE/PE Coated Welded Steel PipeLarge Diameter Spiral Welded Internal FBE External PE Coated Welded Steel Pipe Standard: API 5C...

Details -

concrete weight coating pipe

concrete weight coating pipeConcrete Coated Pipe Type: Concrete Coated Pipe, Concrete Weight Coating Application: Used for natural gas, pet...

Details -

API 5L Line Pipe

API 5L Line PipeAPI 5L Line Pipe Pipe Type: Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe Application: For P...

Details -

Wear-resistant ceramic lining elbow

Wear-resistant ceramic lining elbowAlumina ceramic lined elbow These high wear resistant alumina ceramic lined elbows are to affix withthe alumina c...

Details -

Abrasion resistant ceramic lined pipe and ...

Abrasion resistant ceramic lined pipe and ...90 degree Ceramic lined Elbow with steel pipe for wear resistant Product Descrip...

Details -

Branch Connection fittings

Branch Connection fittingsBranch Connection fittings XINTAI pipeline is a leading manufacturer of branch fitting, buttweld pipe olets, socket ...

Details -

Bimetallic Clad Composite Overlay Hardfac...

Bimetallic Clad Composite Overlay Hardfac...XT PIPELINE Hardfacing Overlay Pipe is manufactured by depositing chromium-rich, abrasion-resistant materials on the...

Details -

Cement Lined Piping

Cement Lined PipingCement lined piping is commonly used for transport of raw water, potable water, sewage, sea water and cooling wat...

Details -

Cast Basalt Pipes and Elbows

Cast Basalt Pipes and ElbowsBasalt is a dark, dense-looking rock, often with small porphyritic crystals, and weathering to a brown co...

Details -

DN125 ST52 concrete pump pipe seamless del...

DN125 ST52 concrete pump pipe seamless del...Overview Quick Details Applicable Industries: Construction works , Construction Machinery & Parts Aft...

Details

Asphalt Enamel Pipe

Published:2018/05/26 Anti-corrosion pipe Steel Pipe 标签:Asphalt EnamelAsphalt Enamel Pipeline Coatingviews:3827

Asphalt Enamel Pipeline Coating

Asphalt Enamel (AE) coating is a plant applied coating based on modified bitumen (asphalt) which has been successfully used for many years for corrosion protection of steel pipes.

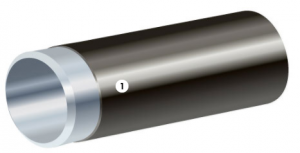

1.Asphalt Enamel

1.Asphalt Enamel

Features & Benefits

Long Term Corrosion Protection

- Excellent adhesion to steel provides a track record of long term corrosion resistance.

- Recommended for pipelines designed to convey water, gas, oil or any other fluid when the continuous temperature of the fluid being transported does not exceed 70°C (158°F)*.

Engineered Solutions

- Advanced manufacturing techniques allow Bredero Shaw to supply AE coatings with varying grades of asphalt enamels and inner and outer wraps along with a thickness as per your design specification.

- The system can be applied to various pipe diameters from 90 mm (3.5”) to over 1200 mm (48”).

Proven Performance

- Extensive track record of excellent performance in over 8,000 enamel pipe coating projects

- More than 80,000 kms (49,710 miles) of enamel coated pipe across the world.

- Proven coating technology for use with Concrete Weight Coatings.

Related Standards and Specifications

- GAZ de France R 01

- EN 10300

- BS 4147

- Shell DEP 31.40.30.33

- DNV RP-F-106

- ISO 9001 :2000

.

Typical Plant Capabilities and Product Properties

| Capablity/Property | Asphalt Enamel |

| Minimum Pipe Diameter | 90 mm (3.5”) |

| Maximum Pipe Diameter | 1200 mm + (48”+) |

| Minimum Pipe Length | 5.5 m (18’) |

| Maximum Pipe Length | 18 m (59’) |

| Minimum Recommended Operating Temperature | -40°C (-40°F) |

| Maximum Recommended Operating Temperature | 70°C (158°F)* |

Values shown are typical and may vary from plant to plant.

* Actual temperature will depend upon design criteria.

Last: HPPC Pipe

Next: LAT-FBE Pipe