-

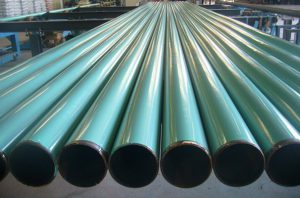

FBE/PE Coated Welded Steel Pipe

FBE/PE Coated Welded Steel PipeLarge Diameter Spiral Welded Internal FBE External PE Coated Welded Steel Pipe Standard: API 5C...

Details -

concrete weight coating pipe

concrete weight coating pipeConcrete Coated Pipe Type: Concrete Coated Pipe, Concrete Weight Coating Application: Used for natural gas, pet...

Details -

API 5L Line Pipe

API 5L Line PipeAPI 5L Line Pipe Pipe Type: Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe Application: For P...

Details -

Wear-resistant ceramic lining elbow

Wear-resistant ceramic lining elbowAlumina ceramic lined elbow These high wear resistant alumina ceramic lined elbows are to affix withthe alumina c...

Details -

Abrasion resistant ceramic lined pipe and ...

Abrasion resistant ceramic lined pipe and ...90 degree Ceramic lined Elbow with steel pipe for wear resistant Product Descrip...

Details -

Branch Connection fittings

Branch Connection fittingsBranch Connection fittings XINTAI pipeline is a leading manufacturer of branch fitting, buttweld pipe olets, socket ...

Details -

Bimetallic Clad Composite Overlay Hardfac...

Bimetallic Clad Composite Overlay Hardfac...XT PIPELINE Hardfacing Overlay Pipe is manufactured by depositing chromium-rich, abrasion-resistant materials on the...

Details -

Cement Lined Piping

Cement Lined PipingCement lined piping is commonly used for transport of raw water, potable water, sewage, sea water and cooling wat...

Details -

Cast Basalt Pipes and Elbows

Cast Basalt Pipes and ElbowsBasalt is a dark, dense-looking rock, often with small porphyritic crystals, and weathering to a brown co...

Details -

DN125 ST52 concrete pump pipe seamless del...

DN125 ST52 concrete pump pipe seamless del...Overview Quick Details Applicable Industries: Construction works , Construction Machinery & Parts Aft...

Details

LAT-FBE Pipe

Published:2018/05/26 Anti-corrosion pipe Steel Pipe 标签:FBE Pipeviews:2634

Low Application Temperature Fusion Bond Epoxy Powder Coating

Low Application Temperature Fusion Bond Epoxy (LAT-FBE ) is a plant applied powder coating for strain based pipeline designs that require a low application temperature. This coating has high operating temperature capabilities, up to 110°C*, combined with superior handling characteristics especially on pipe above 16” outer diameter.

* Dependent on soil and environment conditions

- LAT Fusion Bonded Epoxy

Features & Benefits

Lower Application Temperature

- Applied at a much lower temperature (200°C) than conventional FBE (245°C).

- Maintains steel’s initial design mechanical properties even for high strength pipelines (eg: X80 – X120 steel pipe) LAT FBE can be used as an epoxy primer to support a 3-layer system on high strength steel for tough terrain conditions.

Long term corrosion protection

- FBE’s excellent adhesion to steel provides superior long term corrosion resistance and protection of pipelines operating at moderate temperatures for the designed life.

- The superior adhesion properties also provide excellent resistance to cathodic disbondment which reduces the total cost of cathodic protection during the operation of the pipeline.

Related Standards and Specifications

- CSA Z245.20

- AWWA C 213

- AS3862:2002

- GAZ de France R 09

- GBE/CW 6

- NACE RP 0394

- NF A 49 706

- ISO 10080

- ISO 9001

Typical Plant Capabilities and Product Properties

| Capablity/Property | LAT-FBE |

| Minimum Pipe Diameter | 90 mm (3.5”) |

| Maximum Pipe Diameter | 1220 mm + (48”) |

| Minimum Pipe Length | 5.5 m (18’) |

| Maximum Pipe Length | 25 m (82’) |

| Minimum Recommended Handling & Construction Temperature | -30°C (-22°F)** |

| Maximum Recommended Operating Temperature | 110°C (230°F)* |

Values shown are typical and may vary from plant to plant.

* Soil type, moisture content, temperatures & coating thickness all influence the upper operating temperature limit as per manufacturers’ published literature.

Last: Asphalt Enamel Pipe

Next: 3LPE Pipe