-

FBE/PE Coated Welded Steel Pipe

FBE/PE Coated Welded Steel PipeLarge Diameter Spiral Welded Internal FBE External PE Coated Welded Steel Pipe Standard: API 5C...

Details -

concrete weight coating pipe

concrete weight coating pipeConcrete Coated Pipe Type: Concrete Coated Pipe, Concrete Weight Coating Application: Used for natural gas, pet...

Details -

API 5L Line Pipe

API 5L Line PipeAPI 5L Line Pipe Pipe Type: Line Pipe, API Line Pipe, Seamless Line Pipe, Carbon Steel Line Pipe Application: For P...

Details -

Wear-resistant ceramic lining elbow

Wear-resistant ceramic lining elbowAlumina ceramic lined elbow These high wear resistant alumina ceramic lined elbows are to affix withthe alumina c...

Details -

Abrasion resistant ceramic lined pipe and ...

Abrasion resistant ceramic lined pipe and ...90 degree Ceramic lined Elbow with steel pipe for wear resistant Product Descrip...

Details -

Branch Connection fittings

Branch Connection fittingsBranch Connection fittings XINTAI pipeline is a leading manufacturer of branch fitting, buttweld pipe olets, socket ...

Details -

Bimetallic Clad Composite Overlay Hardfac...

Bimetallic Clad Composite Overlay Hardfac...XT PIPELINE Hardfacing Overlay Pipe is manufactured by depositing chromium-rich, abrasion-resistant materials on the...

Details -

Cement Lined Piping

Cement Lined PipingCement lined piping is commonly used for transport of raw water, potable water, sewage, sea water and cooling wat...

Details -

Cast Basalt Pipes and Elbows

Cast Basalt Pipes and ElbowsBasalt is a dark, dense-looking rock, often with small porphyritic crystals, and weathering to a brown co...

Details -

DN125 ST52 concrete pump pipe seamless del...

DN125 ST52 concrete pump pipe seamless del...Overview Quick Details Applicable Industries: Construction works , Construction Machinery & Parts Aft...

Details

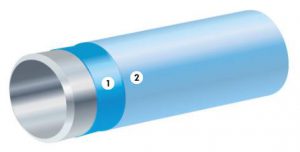

Dual Layer FBE

Published:2018/05/26 Anti-corrosion pipe Steel Pipe 标签:Dual Layer FBEviews:3706

Dual Layer Abrasion Resistant Fusion Bond Epoxy Coating

Dual Layer Abrasion Resistant FBE Systems provide excellent properties for a variety of service applications which may include directional drilling and anti-abrasion for road and river crossings, as well as elevated temperature in wet environments and anti-slip applications.

- Anti-Corrosion Coating 2.Abrasion Resistant Overcoat

Features & Benefits

High operating temperature capabilities

- Dual Layer FBE provides excellent adhesion to steel, providing superior long term corrosion resistance and protection of pipelines operating up to 110°C***.

- The superior adhesion properties of the anticorrosion coating provide excellent resistance to cathodic disbondment, reducing the cost of cathodic protection during the operation of the pipeline.

Excellent abrasion and impact resistance

- Provides excellent abrasion and impact resistance and sufficient flexibility to protect against possible damage to the anti-corrosion coating during pipe transportation, pipeline construction, road bores, and directional drills.

Improved handling characteristics

- Provides tough physical properties that minimize damage during handling, transportation, installation and operation.

Field Bending of Dual Layer FBE is not recommended.

Related Standards and Specifications

- CSA Z245.20

- ISO 9001

Typical Plant Capabilities and Product Properties

| Capablity/Property | Dual Layer FBE |

| Minimum Pipe Diameter | 90 mm (3.5”)* |

| Maximum Pipe Diameter | 1220 mm + (48”+) |

| Minimum Pipe Length | 5.5 m (18’) |

| Maximum Pipe Length | 25 m (80’) |

| Minimum Recommended Handling & Construction Temperature | -30°C (-22°F)** |

| Maximum Recommended Operating Temperature | 110°C (230°F)*** |

Values shown are typical and may vary from plant to plant.

* NPS 3 and 4 depend on wall thickness.

***Soil type, moisture content, temperature & coating thickness all influence the upper operating temperature limit as per manufacture’s published literature.

Last: IPN8710 Water Pipe

Next: HPPC Pipe